Exploring the Scope of Factory Automation

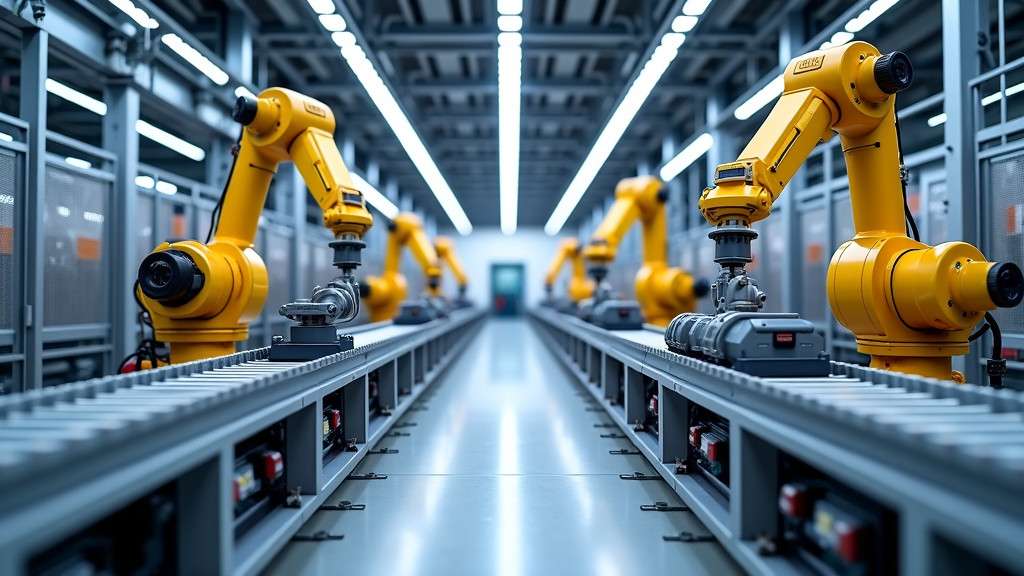

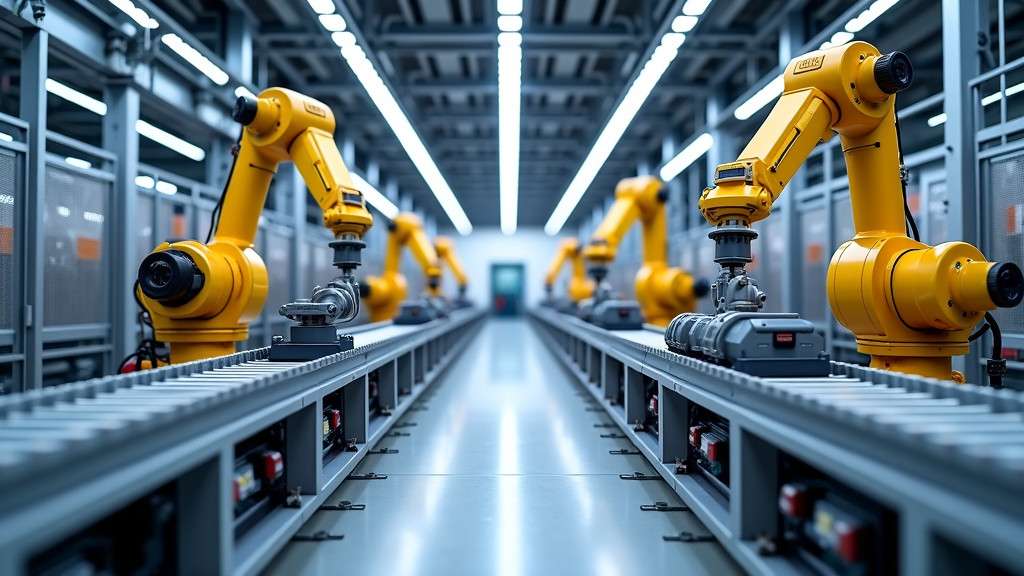

Imagine a manufacturing floor where machines seamlessly communicate, robots precisely assemble products, and production lines adapt in real-time to changing demands. This isn’t science fiction—it’s the reality of modern factory automation.

Factory automation has transformed manufacturing by integrating advanced technology into every aspect of production. It involves smart systems and devices working together to streamline operations, boost efficiency, and reduce costs.

What does factory automation look like in practice? Picture robotic arms performing intricate assembly tasks with precision, while control systems orchestrate the entire production process. These technological marvels are the backbone of automated factories, enabling unprecedented levels of productivity and quality control.

The impact of automation on manufacturing is significant. Recent industry data shows manufacturers have reported up to a 20% increase in output after adopting AI-driven robotics. This surge in productivity is complemented by a potential 15% reduction in manufacturing waste, highlighting the dual benefits of efficiency and sustainability.

This article explores the world of factory automation, examining its key components, transformative effects on industry, and future prospects. Discover how automation is reshaping the foundations of manufacturing.

Main Takeaways:

- Factory automation integrates advanced technology to optimize manufacturing processes

- Robotic arms and control systems are crucial components of automated factories

- Automation significantly boosts productivity and reduces waste in manufacturing

- The impact of automation extends beyond efficiency to improve quality and safety

- Understanding factory automation is essential for staying competitive in modern industry

Key Technologies in Factory Automation

Factory automation relies on several key technologies working in harmony to create efficient production environments. Two crucial systems that form the backbone of many automated factories are hydraulic and pneumatic systems.

Hydraulic systems use pressurized fluids, typically oil, to generate powerful forces. These systems excel at tasks requiring immense strength and precision, like lifting heavy loads or powering industrial presses. Hydraulic actuators provide the muscle behind robotic arms used for heavy-duty material handling on factory floors.

Pneumatic systems harness the power of compressed air. While not as forceful as hydraulics, pneumatic tools and actuators offer advantages in speed, simplicity, and cleanliness. Pneumatics often drive assembly line components, packaging machines, and material conveyors in automated factories.

The integration of these technologies creates a synergy that boosts overall production capabilities. Hydraulics provide the raw power for heavy lifting and precision work, while pneumatics handle rapid, repetitive tasks. This combination allows factories to achieve higher speeds and better quality control across various manufacturing processes.

Beyond hydraulics and pneumatics, modern automated factories incorporate a host of other technologies. Sensors and IoT devices monitor every aspect of production. Sophisticated control systems, often powered by artificial intelligence, coordinate the intricate dance of robotic arms, conveyor belts, and other automated equipment.

As factory automation evolves, we’re seeing even tighter integration between these core technologies. Smart sensors now provide real-time data on hydraulic and pneumatic system performance. This allows for predictive maintenance, reducing costly downtime. The result is a more cohesive, efficient, and adaptable manufacturing environment.

| Aspect | Hydraulic Systems | Pneumatic Systems |

|---|---|---|

| Medium | Pressurized fluid (typically oil) | Compressed air or gas |

| Power Density | Higher, suitable for heavy-load applications | Lower, suitable for light to medium loads |

| Speed and Response Time | Slower due to fluid incompressibility | Faster due to air compressibility |

| Precision and Control | High precision, suitable for accurate movements | Moderate precision |

| Energy Efficiency | More energy-efficient for heavy loads | Less energy-efficient |

| Maintenance | Requires monitoring for leaks and contamination | Requires air treatment and regular maintenance |

| Applications | Heavy-duty tasks like industrial presses | Assembly line components, packaging machines |

Benefits of Implementing Automation in Factories

A photorealistic view of a futuristic factory with advanced automated machinery and sleek design. – Artist Rendition

Automation is reshaping production floors across industries, making it a key factor in modern manufacturing. Here are the compelling advantages that make automation a game-changer for factories.

Supercharging Productivity and Efficiency

Automation significantly boosts productivity by allowing systems to operate continuously, without breaks. This results in higher output rates than traditional manual processes. A McKinsey study found that leading factories in automation saw output improvements from 20% to 140%. Automation also ensures consistency and precision, reducing errors and waste.

Slashing Costs and Boosting the Bottom Line

Though the initial investment in automation can be high, the long-term savings are substantial. Automation reduces the need for manual labor, lowering operational costs. It also improves resource efficiency, reducing waste and utility bills. For example, Arçelik achieved a 35% reduction in greenhouse gas emissions and a 20% cut in water usage with automation.

Enhancing Workplace Safety

Automation can create safer work environments by handling dangerous tasks, reducing the risk of injuries. Robots can manage hazardous materials and extreme conditions, allowing human workers to focus on safer, more engaging tasks. Automation can reduce manufacturing injuries by up to 72%, lowering insurance costs and improving morale.

Empowering the Workforce

Rather than replacing workers, automation shifts job types, increasing demand for skilled roles in programming and system maintenance. This transition offers opportunities for upskilling and higher-paying jobs. For instance, Kordsa reported a 30% reduction in low-value task hours, enabling employees to focus on strategic work.

Automation isn’t about replacing humans – it’s about augmenting their capabilities and allowing them to focus on what they do best: innovate, problem-solve, and drive the business forward.

Industry expert at a recent manufacturing conference

Key Benefits at a Glance

- Significantly increased productivity (20-140% in some cases)

- Improved product quality and consistency

- Substantial cost savings through efficient resource use

- Enhanced workplace safety (up to 72% reduction in injuries)

- Creation of new, higher-skilled job opportunities

- Increased global competitiveness

Automation is set to play a vital role in the factories of tomorrow. By adopting these technologies, manufacturers can enhance productivity, safety, and innovation, maintaining competitiveness in the global marketplace.

| Aspect | Manual Processes | Automated Systems |

|---|---|---|

| Speed | Slower, dependent on human effort | Faster, consistent, 24/7 operation |

| Accuracy | Prone to human error | High precision, minimal errors |

| Cost | Lower initial cost, higher operational costs | Higher initial cost, lower long-term operational costs |

| Scalability | Limited, requires more labor | Highly scalable, handles increased demand |

| Flexibility | High, adaptable to changes | Low, requires reprogramming for changes |

| Employee Impact | More jobs, less skill development | Fewer routine jobs, more skilled opportunities |

Challenges in Adopting Full-scale Automation

A high-tech factory floor showcasing collaboration between human workers and advanced machinery. – Artist Rendition

Automation promises to streamline operations, but its implementation presents hurdles. Two significant challenges are the substantial initial setup costs and workforce adaptation complexities. Let’s explore these obstacles and how companies can navigate them effectively.

Grappling with High Upfront Costs

The financial investment for full-scale automation can be daunting. According to a recent study, the initial capital outlay for technology, infrastructure upgrades, and employee training poses financial challenges, especially for small and medium-sized enterprises (SMEs).

These costs often include:

- Purchase of advanced machinery and robotics

- Software systems and integration

- Facility modifications

- Comprehensive employee training programs

Despite long-term savings, many companies struggle to justify the substantial upfront investment, potentially delaying adoption and putting them at a competitive disadvantage.

| Component | Cost Range |

|---|---|

| Initial Setup Fees | $2,000 – $10,000 |

| Monthly Fees | $200 – $2,000 |

| Licensing Costs | Minimum $20,000/year |

| Implementation Costs | $15,000 – $150,000 per process |

| Support Services | $2,000 – $8,000/month |

| Hardware Expenses | $20,000 – $150,000 |

| Software & Licensing | $10,000 – $50,000 |

| Maintenance & Support | 15-20% of original hardware and software expenses |

Navigating Workforce Adaptation

Beyond financial aspects, the human element of automation adoption is challenging. Workforce adaptation involves overcoming several hurdles:

1. Resistance to change: Employees often fear job displacement, leading to apprehension about new technologies. Open communication about automation’s role and benefits is crucial.

2. Skills gap: As technology evolves, workers need ongoing training to adapt. Providing resources for upskilling is vital for a smooth transition.

3. Redefining roles: Automation shifts work nature, requiring employees to transition from manual tasks to supervisory and maintenance roles, which can be psychologically challenging.

Strategies for Overcoming Automation Challenges

To address these challenges, companies can consider the following approaches:

1. Phased implementation: Gradually automating one process at a time allows for better cost management and gives the workforce time to adapt.

2. Investment in training: Allocating resources for comprehensive training programs helps bridge the skills gap and reduces resistance to change. Companies like Amazon and Tesla have successfully implemented extensive retraining initiatives.

3. Collaborative approach: Involving employees in the automation process can foster a sense of ownership and reduce anxiety. Encouraging feedback and suggestions from workers can lead to more effective implementation strategies.

4. Focus on value-added tasks: Emphasize how automation frees employees to focus on more rewarding, creative aspects of their jobs. This perspective shift can help alleviate fears of job loss and increase enthusiasm for new technologies.

By addressing these challenges head-on, companies can pave the way for successful automation adoption, reaping increased efficiency and productivity while maintaining a motivated and skilled workforce.

SmythOS: Enhancing Automation Development

SmythOS is transforming enterprise technology with its innovative approach to AI orchestration and automation. This platform integrates multiple AI models, APIs, and data sources, enabling businesses to create sophisticated automation workflows without extensive coding knowledge.

SmythOS connects various AI applications and traditional SaaS tools through a unified interface. This allows companies to leverage different AI models for tasks like content creation and data analysis within a single ecosystem.

One of SmythOS’s standout features is its visual builder, enabling users to design complex AI workflows through an intuitive drag-and-drop interface. This democratizes AI development, making it accessible to professionals across various departments.

The platform’s monitoring capabilities provide real-time insights into AI agent performance, allowing businesses to track efficiency, identify bottlenecks, and optimize automated processes. This oversight ensures AI-driven workflows align with business objectives and deliver measurable results.

SmythOS also addresses the growing need for AI education in the workplace. Through initiatives like the SmythOS Academy, the company bridges the knowledge gap, helping professionals understand and harness AI effectively.

As enterprises navigate rapid AI advancements, SmythOS stands out as a comprehensive solution providing tools for automation development and fostering the skills needed to leverage them. By combining cutting-edge technology with accessible education, SmythOS is paving the way for AI-driven automation to become integral to every business strategy.

Conclusion and Future of Factory Automation

A photorealistic depiction of a futuristic automated factory interior showcasing the integration of human operators and robotic systems. – Artist Rendition

Looking ahead, factory automation is set to transform manufacturing in unprecedented ways. The convergence of artificial intelligence, the Internet of Things (IoT), and advanced robotics will create smart factories that are more efficient, flexible, and productive.

AI-powered predictive maintenance systems are a promising development. By 2025, these algorithms could reduce downtime by up to 50%, allowing for near-continuous production. Picture assembly lines that anticipate and prevent breakdowns, optimizing output and reducing costs.

Digital twin technology will also shape future factories. These virtual replicas of physical systems will enable manufacturers to simulate and optimize production processes with great accuracy. A PwC study suggests that digital twins could boost defect detection rates by 90%, ensuring exceptional quality control.

As 2025 approaches, we will see changes in workforce dynamics within manufacturing. Automation will augment human capabilities, allowing workers to focus on tasks requiring creativity and critical thinking. Industry leaders predict that 70% of manufacturing employees will undergo AI-related upskilling programs, creating a new breed of tech-savvy industrial workers.

The future of factory automation is about more than technological advancements; it’s about reimagining manufacturing itself. As these innovations take hold, we’ll see agile, sustainable, and hyper-efficient production ecosystems that respond to market changes in real time. The possibilities are limitless, and the coming years promise an exciting journey toward a smarter, more connected industrial landscape.

Last updated:

Disclaimer: The information presented in this article is for general informational purposes only and is provided as is. While we strive to keep the content up-to-date and accurate, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability of the information contained in this article.

Any reliance you place on such information is strictly at your own risk. We reserve the right to make additions, deletions, or modifications to the contents of this article at any time without prior notice.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data, profits, or any other loss not specified herein arising out of, or in connection with, the use of this article.

Despite our best efforts, this article may contain oversights, errors, or omissions. If you notice any inaccuracies or have concerns about the content, please report them through our content feedback form. Your input helps us maintain the quality and reliability of our information.