Autonomous agents are transforming manufacturing in exciting new ways. These smart systems help factories run smoother, faster, and with better quality than ever before. But what exactly are autonomous agents, and how are they changing the manufacturing world?

Picture tiny digital workers that never get tired and can make lightning-fast decisions. That’s essentially what autonomous agents are—intelligent software programs that can sense their environment, make choices, and take actions without constant human oversight. In manufacturing, they’re being put to work on all kinds of important jobs.

One key area where autonomous agents shine is predictive maintenance. These smart systems can monitor factory equipment around the clock, detecting early warning signs of potential breakdowns. By flagging issues before they cause problems, autonomous agents help keep production lines humming and avoid costly shutdowns.

Quality control is another place where autonomous agents are making a big difference. With superhuman vision and tireless attention to detail, they can spot defects that human inspectors might miss. This leads to higher quality products and fewer costly recalls or customer complaints.

Autonomous agents are also revolutionizing supply chain management. They can track inventory levels, predict future demand, and automatically reorder supplies as needed. This keeps factories stocked with exactly what they need, when they need it.

While the potential benefits are huge, integrating autonomous agents into existing manufacturing processes isn’t always easy. It requires significant investment in new technology and retraining of workers. There are also concerns about cybersecurity and job displacement to consider.

Still, for manufacturers looking to stay competitive in today’s fast-paced global market, autonomous agents offer an exciting path forward. As these technologies continue to evolve, they promise to make factories smarter, more efficient, and more responsive to changing customer demands than ever before.

Streamlining Production Processes with AI Agents

The manufacturing industry is transforming with the integration of artificial intelligence (AI) agents into production processes. These intelligent systems bring unprecedented efficiency and productivity to the shop floor.

AI agents analyze vast amounts of production data from sensors, machinery, and enterprise systems. By processing this data in real-time, they identify inefficiencies, bottlenecks, and optimization opportunities that human managers might miss. This data-driven approach allows for continuous workflow improvement and rapid adjustments to changing conditions.

One key way AI agents streamline production is through predictive maintenance. By monitoring equipment performance data, these systems can forecast when a machine is likely to fail and schedule maintenance before a breakdown occurs. This proactive approach minimizes unplanned downtime and keeps production lines running smoothly.

Quality control is another area where AI agents excel. Computer vision systems inspect products with superhuman speed and accuracy, catching defects that might slip past human inspectors. This improves overall product quality and reduces waste and rework, leading to significant cost savings.

Supply chain optimization is another powerful application of AI in manufacturing. These intelligent systems analyze market trends, inventory levels, and supplier performance to make smarter purchasing and logistics decisions. This ensures that the right materials are in the right place at the right time, reducing delays and inventory costs.

Real-World Impact

Many manufacturers are already reaping the rewards of AI-driven production optimization. For example, one automobile manufacturer found that an AI-based visual inspection system identified defects with up to 97% accuracy, compared to 70% for human inspectors. This improvement in quality control has led to higher customer satisfaction and reduced warranty costs.

Similarly, a mining company used AI-driven solutions to predict maintenance needs, reducing production downtime by up to 30%. This translated into millions of dollars in saved revenue and greatly improved operational efficiency.

Implementing AI Agents in Your Factory

Successfully implementing AI systems requires careful planning and execution. Here are a few key considerations:

- Start with a clear strategy and defined objectives for AI implementation

- Ensure you have high-quality, relevant data to feed your AI systems

- Invest in the necessary infrastructure and integrate AI with existing systems

- Train employees on working alongside AI agents and interpreting their insights

- Prioritize data security and privacy in your AI implementations

Consider the unique challenges and bottlenecks in your operations. Where could real-time data analysis and predictive capabilities make the biggest impact? The potential for optimization is vast, limited only by our imagination and willingness to embrace these transformative technologies.

By harnessing the power of AI agents, manufacturers can create smarter, more efficient production lines that adapt quickly to change and consistently deliver high-quality output. The future of manufacturing is here, and it’s powered by artificial intelligence.

Enhancing Quality Control and Reducing Human Error

Imagine a world where every product you buy is flawless, free from defects, and meets the highest quality standards. This is the reality that AI-powered quality control is bringing to manufacturing today.

AI agents are transforming quality control processes across industries. These intelligent systems use advanced computer vision and machine learning algorithms to inspect products with superhuman accuracy and speed. But what makes them truly game-changing?

Unmatched Inspection Accuracy

AI doesn’t get tired, distracted, or have ‘off days’ like human inspectors might. These tireless digital quality controllers can spot the tiniest imperfections that even the keenest human eye could miss. Whether it’s a microscopic crack in a smartphone screen or a slight color variation in food packaging, AI catches it all.

Manufacturers are seeing dramatic improvements in defect detection rates. One automotive parts maker reported a 90% reduction in defective components slipping through after implementing AI-powered visual inspection. This level of accuracy ensures that only the highest quality products make it to consumers.

Consistency is Key

Human quality control can be inconsistent. What one inspector might flag as a defect, another might overlook. AI eliminates this variability. Once trained on what constitutes a defect, an AI system applies those criteria consistently, 24/7, across every single product.

This consistency is crucial in industries where even slight variations can have serious consequences. In pharmaceutical manufacturing, for example, AI ensures that every pill, capsule, and vial meets exact specifications, potentially saving lives.

Speeding Up Production Without Sacrificing Quality

Traditional quality control often creates bottlenecks in production. Human inspectors can only work so fast, and increasing speed often leads to more errors. AI breaks this trade-off.

A food processing plant I visited recently shared how their AI quality control system inspects thousands of products per minute with greater accuracy than their previous manual process. This allows them to ramp up production speeds without compromising on quality—a win-win for both the manufacturer and the consumer.

Learning and Improving Over Time

Perhaps the most exciting aspect of AI in quality control is its ability to learn and improve. These systems continuously analyze data from inspections, identifying new patterns and refining their detection capabilities.

As one quality control manager put it, “Our AI doesn’t just maintain quality standards—it helps us raise the bar over time.” This constant evolution means manufacturers can stay ahead of emerging quality issues and continually enhance their products.

The Human Touch: Augmented, Not Replaced

It’s important to note that AI isn’t replacing human expertise in quality control—it’s enhancing it. AI handles the repetitive, high-volume inspection tasks, freeing up human quality experts to focus on more complex problems, process improvements, and strategic decision-making.

This partnership between human insight and AI precision is creating a new gold standard in manufacturing quality. As AI continues to evolve, we can look forward to a future where product defects become increasingly rare, and ‘premium quality’ becomes the norm rather than the exception..

Improving Supply Chain Management

Supply chain management has become increasingly challenging. Companies must juggle countless moving parts, from forecasting demand to managing inventory and coordinating logistics. Enter AI agents: the game-changing technology transforming how businesses handle these intricate processes.

AI-powered supply chain management leverages sophisticated algorithms to analyze vast amounts of data. This data-driven approach enables companies to make smarter, more informed decisions across their entire supply chain. Here are some key ways AI is transforming this critical business function:

Demand Forecasting: Predicting the Future

One of AI’s most powerful applications in supply chain management is demand forecasting. Traditional forecasting methods often fall short, relying on historical data that may not account for rapidly changing market conditions. AI agents, on the other hand, can process enormous datasets, including real-time market trends, social media sentiment, and even weather patterns, to generate highly accurate demand predictions.

This enhanced forecasting capability allows businesses to optimize their inventory levels, reducing the risk of overstocking or stockouts. For example, an AI system might detect an emerging fashion trend on social media and adjust production plans accordingly, ensuring the right products are available when consumer demand spikes.

By aligning supply more closely with actual demand, companies can significantly reduce waste and improve their bottom line. It’s a win-win for both businesses and consumers.

Inventory Optimization: The Goldilocks Zone

Managing inventory is a delicate balancing act. Too much inventory ties up capital and risks obsolescence, while too little can lead to missed sales opportunities and dissatisfied customers. AI agents excel at finding that ‘just right’ sweet spot.

These intelligent systems continuously monitor inventory levels across multiple locations, factoring in variables like seasonality, lead times, and even geopolitical events that could disrupt the supply chain. By analyzing this complex web of factors, AI can recommend optimal inventory levels and automatically trigger reorders when necessary.

Moreover, AI-driven inventory management goes beyond simple stock levels. It can also suggest the best allocation of inventory across different warehouses or stores based on localized demand patterns. This granular level of optimization was simply not possible with traditional inventory management systems.

Streamlining Logistics: The Road to Efficiency

Logistics, the movement of goods from point A to point B, is often the most complex and costly part of supply chain management. AI is proving to be a powerful ally in streamlining these operations.

For instance, AI agents can optimize routing for delivery vehicles, taking into account factors like traffic patterns, weather conditions, and delivery priorities. This not only reduces fuel costs and delivery times but also improves overall customer satisfaction.

In warehouses, AI-powered robots and computer vision systems are revolutionizing picking and packing processes. These systems can work tirelessly, with greater accuracy than their human counterparts, significantly speeding up order fulfillment.

Perhaps most impressively, AI can provide end-to-end visibility across the entire supply chain. By integrating data from various sources, such as suppliers, transportation providers, warehouses, and retailers, AI creates a holistic view of the entire process. This visibility allows for quick identification and resolution of bottlenecks or disruptions.

Enhancing Manufacturing Synchronization

In manufacturing, timing is everything. AI agents excel at synchronizing various production processes, ensuring that each step in the manufacturing chain is optimized for maximum efficiency.

By analyzing data from sensors on production equipment, AI can predict maintenance needs before breakdowns occur, minimizing costly downtime. It can also adjust production schedules in real-time based on changes in demand or supply chain disruptions, ensuring resources are always being used most effectively.

This level of synchronization extends beyond the factory floor. AI can coordinate with suppliers to ensure raw materials arrive just when they’re needed, reducing storage costs and the risk of stockouts.

| Advantage | Description |

|---|---|

| Predictive Maintenance | AI predicts equipment failures, minimizing downtime and ensuring efficient production. |

AI is not just improving supply chain management; it’s fundamentally transforming it. By harnessing the power of data and advanced algorithms, businesses can create more responsive, efficient, and resilient supply chains. This ability to adapt and optimize in real-time isn’t just a competitive advantage; it’s becoming a necessity for survival in the global marketplace.

Boosting Worker Safety

Worker safety in manufacturing is a paramount concern. With artificial intelligence (AI), factories are transforming their safety measures. AI agents are invaluable in creating safer work environments, offering capabilities beyond traditional safety protocols.

AI enhances worker safety through advanced hazard identification. Unlike human observers who may miss subtle danger signs due to fatigue or distraction, AI systems tirelessly monitor the work environment. These digital sentinels use computer vision and machine learning algorithms to analyze vast amounts of data in real-time, spotting potential risks before they escalate into accidents.

For instance, AI-powered cameras can detect when a worker enters a restricted area or approaches dangerous machinery without proper protective equipment. The system can then instantly alert supervisors or trigger automated safety responses, potentially preventing serious injuries. This proactive approach to hazard identification marks a significant leap forward in workplace safety management.

Beyond identifying hazards, AI agents promote and enforce safe practices. Through continuous monitoring and analysis of worker behavior, these systems can identify patterns of unsafe actions or non-compliance with safety protocols. This data is invaluable for targeted safety training and creating more effective safety policies.

Consider a scenario where an AI system notices that workers in a particular shift consistently forget to wear safety goggles. It can flag this trend, allowing managers to address the issue through focused reminders or additional training. This level of granular insight helps create a culture of safety tailored to each workplace’s specific needs and challenges.

Automation of Hazardous Tasks

AI contributes to worker safety by taking over dangerous tasks. In many manufacturing environments, there are jobs that inherently carry high risks, such as tasks involving extreme temperatures, toxic substances, or heavy machinery. AI-powered robots and autonomous systems can now handle many of these hazardous operations, significantly reducing the exposure of human workers to potential harm.

For example, in chemical plants, AI-driven robots can manage the handling and processing of corrosive or toxic materials. In automotive manufacturing, AI-controlled robotic arms can perform welding tasks that traditionally exposed workers to intense heat and harmful fumes. By relegating these high-risk tasks to machines, companies can dramatically reduce workplace accidents and long-term health risks for their employees.

AI’s goal in workplace safety isn’t to replace human workers but to complement and protect them. While machines take on the most dangerous tasks, human workers can focus on roles requiring creativity, decision-making, and interpersonal skills, areas where humans excel over machines.

AI is not just a tool for efficiency; it’s becoming a guardian of worker well-being, creating environments where safety is woven into the very fabric of daily operations.

The future integration of AI in manufacturing safety promises even more advanced applications. Predictive analytics could allow AI systems to forecast potential safety issues based on historical data and current conditions. Wearable AI devices could monitor workers’ vital signs and fatigue levels, alerting them to take breaks before exhaustion sets in. The possibilities are numerous.

AI is transforming worker safety in manufacturing. Through superior hazard identification, promotion of safe practices, and automation of dangerous tasks, AI agents are creating safer, more secure workplaces. As these technologies evolve, workplace accidents will become increasingly rare, ensuring every worker can return home safely at the end of their shift.

Conclusion: The Future of Autonomous Agents in Manufacturing

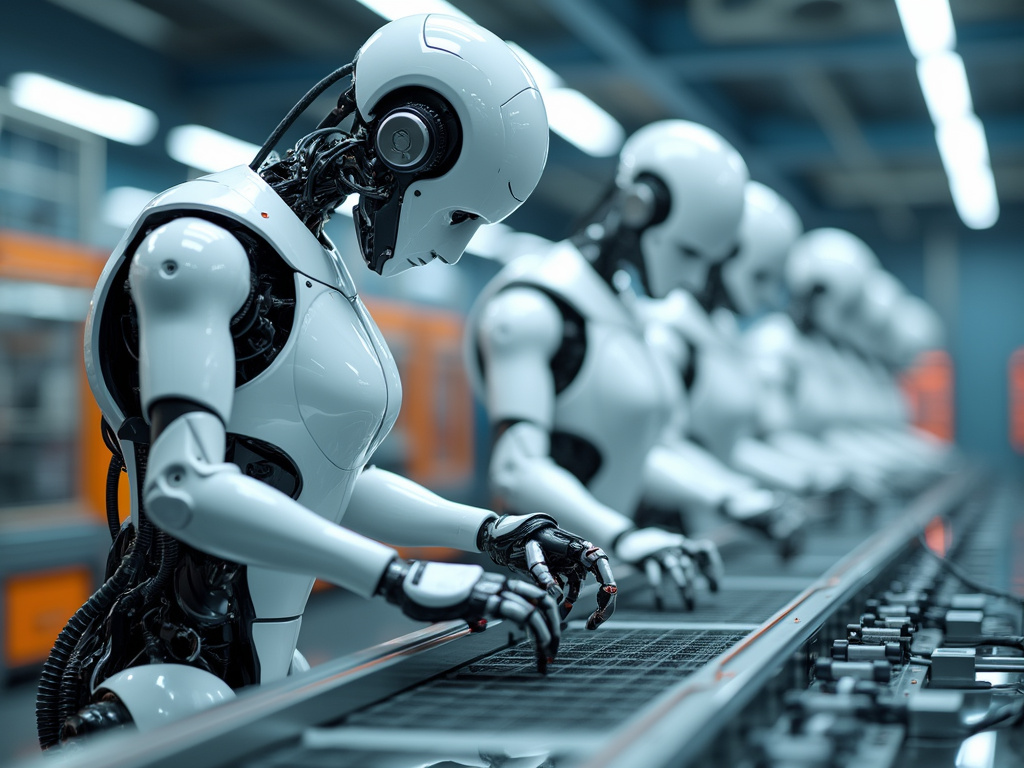

Autonomous robots collaborating in a high-tech assembly line.

Autonomous agents are set to transform manufacturing, bringing a future of unprecedented efficiency, quality, and safety. These AI-powered systems enable production lines that not only run themselves but continuously learn and improve. By analyzing vast amounts of data in real-time, autonomous agents can make split-second decisions that optimize every aspect of the manufacturing process.

From predictive maintenance that prevents costly breakdowns to quality control systems detecting defects beyond human capacity, these agents promise a significant shift in how we make things. However, implementing autonomous agents requires careful planning, investment, and openness to change. Platforms like SmythOS provide the infrastructure and support necessary to bridge the gap between cutting-edge AI and practical applications.

By leveraging tools like SmythOS, manufacturers can integrate autonomous agents without technical complexities, democratizing access to AI advancements for companies of all sizes. Embracing autonomous agents positions manufacturers to thrive in an increasingly competitive global market, making the future of manufacturing autonomous, adaptive, and highly intelligent. Now is the time to explore this technology, turning future challenges into opportunities for growth and innovation.